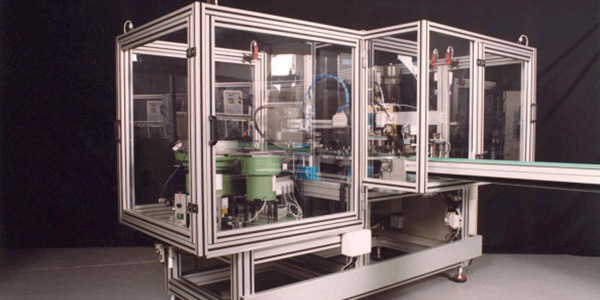

Terminal assembly automation

Automatic machine for the assembly of airbag bridge terminals

Semi-automatic rotary machine with manual loading for the automatic assembly and pressing of terminals.

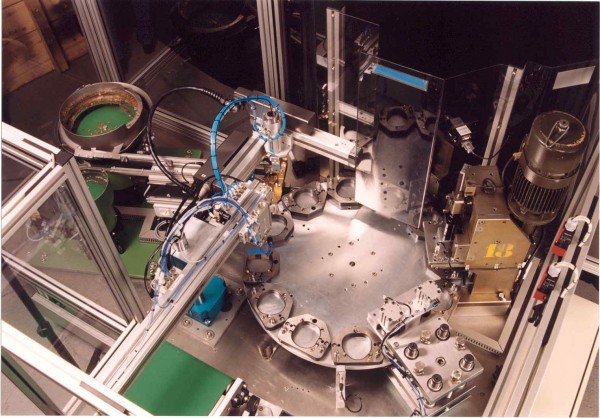

In the first station, the assembly of the terminal and the rivet is carried out, and they are transferred to each of the housings arranged in the tool. To do this, a servomotorized system with 2 X-Y axes plus a 7-position rotary pneumatic system is used.

Once the terminals have been placed, in a fully protected station, the operator places the "airbag bridge" part on the tool, so that the terminals are under the part.

In the next station, the terminals are riveted on the piece by means of an eccentric press, later it is verified and at the end the OK pieces are evacuated towards a transport belt.

The approximate cycle is 2.1 seconds per terminal.

In the first station, the assembly of the terminal and the rivet is carried out, and they are transferred to each of the housings arranged in the tool. To do this, a servomotorized system with 2 X-Y axes plus a 7-position rotary pneumatic system is used.

Once the terminals have been placed, in a fully protected station, the operator places the "airbag bridge" part on the tool, so that the terminals are under the part.

In the next station, the terminals are riveted on the piece by means of an eccentric press, later it is verified and at the end the OK pieces are evacuated towards a transport belt.

The approximate cycle is 2.1 seconds per terminal.

.jpg)

.jpg)

![[...]](http://www.netiserra.com/xtra/imgs/loading.gif)